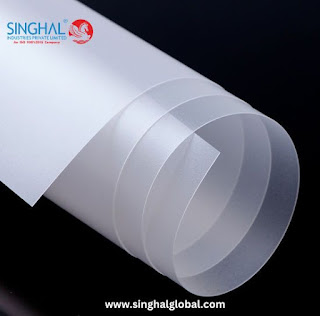

Plastic polypropylene (PP) sheets have emerged as indispensable materials across various industries, owing to their versatility, durability, and cost-effectiveness. In this comprehensive guide, we delve into the world of plastic PP sheets, exploring their properties, applications, benefits, and innovative uses in modern manufacturing. When sourcing top-quality PP sheets, it's essential to partner with a reputable PP sheet manufacturer to ensure reliability and performance in your projects.

Understanding Plastic PP Sheets:

Plastic PP sheet are thermoplastic polymers made from polypropylene resin. They are manufactured through processes like extrusion or compression molding, resulting in sheets with a wide range of thicknesses, sizes, and surface finishes. PP sheets exhibit excellent chemical resistance, impact strength, and thermal stability, making them suitable for diverse applications.

Properties of Plastic PP Sheets:

Chemical Resistance: PP sheets are highly resistant to a wide range of chemicals, acids, and solvents, making them ideal for applications in corrosive environments.

Impact Strength: Plastic PP sheets offer excellent impact resistance, ensuring durability and reliability in high-stress applications.

Thermal Stability: PP sheets can withstand a wide range of temperatures, making them suitable for both indoor and outdoor use.

Lightweight: Plastic PP sheets are lightweight yet sturdy, offering ease of handling and installation in various projects.

Recyclability: PP is a recyclable material, contributing to sustainability and environmental responsibility in manufacturing processes.

Applications of Plastic PP Sheets:

Packaging: PP sheets are widely used in packaging applications, including food packaging, pharmaceutical packaging, and industrial packaging, owing to their moisture resistance and durability.

Signage and Displays: PP sheets are used to create signage, displays, and advertising boards due to their smooth surface finish and excellent printability.

Construction: PP sheets find applications in construction for roofing, wall cladding, and insulation, providing weather resistance and thermal insulation properties.

Automotive: PP sheets are used in automotive interiors, such as door panels, dashboard components, and trunk liners, for their lightweight and impact-resistant properties.

Stationery: PP sheets are commonly used in stationery products like folders, binders, and dividers due to their flexibility and durability.

Benefits of Plastic PP Sheets:

Cost-Effectiveness: PP sheets offer cost-effective solutions for various applications compared to other materials like metal or glass.

Versatility: Plastic PP sheets can be easily fabricated, molded, and machined into different shapes and sizes to meet specific project requirements.

Durability: PP sheets are resistant to moisture, chemicals, and impact, ensuring long-lasting performance in challenging environments.

Lightweight: The lightweight nature of PP sheets reduces transportation costs and facilitates ease of handling and installation.

Recyclability: PP is a recyclable material, contributing to circular economy principles and sustainable manufacturing practices.

Innovations in Plastic PP Sheets:

Enhanced Additives: Manufacturers are incorporating additives into PP sheets to enhance properties like UV resistance, flame retardancy, and antimicrobial properties.

Multilayer Structures: Multilayer PP sheets are being developed with improved barrier properties for packaging applications, extending the shelf life of perishable goods.

Biodegradable PP: Research is ongoing to develop biodegradable PP materials to address environmental concerns and reduce dependency on fossil fuels.

Conclusion:

Plastic PP sheets have become indispensable materials across various industries due to their versatility, durability, and cost-effectiveness. With their excellent properties and innovative applications, PP sheets continue to play a crucial role in modern manufacturing and product design. As technology advances and new innovations emerge, the potential of plastic PP sheets is boundless, shaping a more sustainable and resilient future for industries worldwide. For reliable access to high-quality PP sheets, consider partnering with a trusted PP sheet manufacturer in Delhi to meet your specific needs and requirements.

Frequently Asked Questions (FAQs):

1. What distinguishes Singhal Industries' plastic PP sheets from other options on the market?

Singhal Industries' plastic PP sheets are manufactured using high-quality polypropylene resin and state-of-the-art manufacturing processes, ensuring superior quality, durability, and consistency in performance compared to other alternatives.

2. Can Singhal Industries customize plastic PP sheets to meet specific project requirements?

Yes, Singhal Industries offers customization options for plastic PP sheets to accommodate the unique needs of different projects. Whether it's size, thickness, color, or surface finish, our team can tailor the sheets to meet specific project specifications and applications.

3. How can I order plastic PP sheets from Singhal Industries?

Ordering plastic PP sheets from Singhal Industries is simple and convenient. Customers can reach out to our sales team directly or visit our website to explore our product range and place an order. With competitive pricing, reliable delivery, and exceptional customer service, Singhal Industries ensures a seamless purchasing experience for our clients.

Comments

Post a Comment